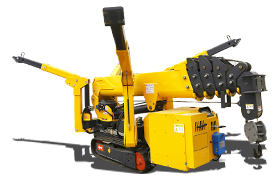

SDBS Series Miniature Price Of Concrete Hose Pump truck Small Diesel

Tel: +86-15065371072

Email: business@chinacoalintl.com

Share

Share

Introduction of SDBS Series Miniature Concrete Pump

The construction site fine stone mortar pump is applied in high-rise building ash mortar and fine stone concrete transportation, secondary structure column grouting, reservoir, hydropower station, port, dock, various pressure grouting, foundation treatment, weak foundation, reinforcement grouting, tunnel Backfill grouting anchor support in subway and mine construction. Other descriptions This product adopts hydraulic feeding, and the double-cylinder reciprocating operation of vibrating net filter can completely transport various mortars, fine stone concrete, etc. in building application. This product has large displacement, high pressure, labor saving, flexible movement, etc. Features, is an ideal mortar conveying equipment. The pump is widely used in indoor construction of urban construction projects (such as infusion of structural columns and invisible columns), anchorage grouting, consolidation grouting and backfill grouting works for underground tunnels of urban subway hydropower stations. It can also be used for grouting of anchor piles during slope and soft rock reinforcement.

Concrete transmission and use are generally divided into: HBT60, 80 concrete pump for piling and hitting the building, ground and floor heating, 15, 20, 30 fine stone concrete pump for fine stone.

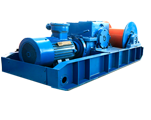

Motor concrete pump: HBT60-13-90------HBT (trail concrete pump), 60 (maximum pumping efficiency 60 m³ /h), S (S-tube dispensing valve); 13 (outlet concrete maximum Pressure 13Mpa; 90 (motor power 90Kw)

Diesel concrete pump: HBTS60-13-112R HBT (trailed concrete pump), 60 (maximum pumping efficiency 60 m³ /h), S (S-tube dispensing valve); 13 (maximum pressure of outlet concrete 13Mpa; 112 (motor Power 112Kw) R (diesel engine)

The main technical parameters of SDBS Series Miniature Concrete Pump

Project | Unit | SDBS10 | SDBS20 | SDBS40 |

Maximum theoretical delivery | m³/h | 8 | 20 | 40 |

Maximum theoretical transport distance | m | 100/300 | 100/300 | 200/800 |

Maximum outlet pressure | Mpa | 10 | 8 | 12 |

Motor Power | kw | 22 | 30 | 55 |

Feeding height | mm | 1000 | 1200 | 1200 |

Pumpable concrete maximum particle size | mm | ≤30 | ≤50 | ≤40 |

Most suitable for pumping concrete slump | cm | 15-23 | 15-23 | 15-23 |

Duct inner diameter | mm | Φ125 | Φ125 | Φ125 |

Host weight | Kg | 1500 | 1900 | 3400 |

Dimensions: length × width × height | mm | 2100×1160×1800 | 3300×1600×1800 | 4300×1600×1800 |

SDBS Series Miniature Price Of Concrete Hose Pump truck Small Diesel

SDBS Series Miniature Price Of Concrete Hose Pump truck Small Diesel