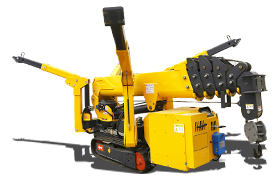

DR1000-6 Wire Rope Transmission Wall Finishing Machine Cement Plaster Machine

Tel: +86-15065371072

Email: business@chinacoalintl.com

Share

Share

Introduction Of DR1000-6 Wire Rope Transmission Wall Finishing Machine Cement Plaster Machine

Wall Plastering Machine uses the conveyor belt to transport the ash forward and upwards, which can be completely wiped to the top (without leaving 1 mm) and completely wiped to the top with the conveyor belt. The conveyor belt can be manually stopped or supply ash at any position, realizing the plastering of windows up and down, and above the door (Note: There must be a distance of at least 50cm on the doors and windows, because the conveyor belt is 45cm from the top and automatically stops supplying ash). Insufficient ash causes secondary repainting after lack of ash on the wall, and can also deliver ash intermittently to reduce the falling ash during the ascent.

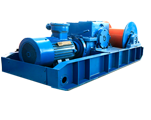

Parameter Of DR1000-6 Wire Rope Transmission Wall Finishing Machine Cement Plaster Machine

Plastering thickness | 2-45(mm) | Plastering width | 1000mm | Plastering efficiency | 600²/8H | |||

Voltage | 380/220 | Motor power | 2.2kv | Plastering height | Below 5m | |||

Overall dimension of main engine | 1250×1000×550 | Main engine weight | 190kg | | | |||

Main machine packing box size | 1320×1170×720 | Weight of main engine packing box | 40kg | Total weight of main engine (with packing box) | 230kg | |||

Dimension of vertical pole packing box | 2500×250×260 | Weight of vertical pole packing box | 17kg | Total weight of vertical pole box (with packing box) | 70kg | |||

Total weight of machine | 300kg | Machine general | 1.3m³ | |||||

DR1000-6 Wire Rope Transmission Wall Finishing Machine Cement Plaster Machine

DR1000-6 Wire Rope Transmission Wall Finishing Machine Cement Plaster Machine