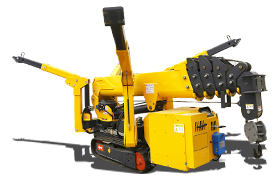

There are many projects in summer, which is precisely the season of frequent mini excavator failures. "Three high" is the common fault of mini excavator construction in summer, and is the main factor leading to failure and shutdown.

The temperature of the water tank is too high, commonly known as "boiling". "Boiling" affects the normal heat dissipation of the engine, and then causes the high temperature expansion and deformation of the parts in the engine, such as the piston and piston ring are blocked by thermal expansion, and the high temperature intensifies the oxidation of the oil and accelerates the wear of the moving parts. To prevent "boiling", the old drivers have their own tricks. Some refit the water tank, some add air cooling, and some simply remove the cover of the water tank.

In fact, on the premise of not damaging the beauty, the correct use of antifreeze can effectively avoid boiling. The antifreeze has two characteristics: low freezing point and high boiling point. Therefore, it can not only ensure the normal operation of the vehicle system in winter, but also prevent the cooling water from boiling in summer. The anti-rust and anti-corrosion functions of the antifreeze can also slow down the aging of the entire cooling system, and the waterproof scale function can prevent the scale from blocking the circulating pipeline.

When the temperature of hydraulic oil is too high, the viscosity, lubricity and wear resistance of the oil will obviously decrease, which will not only lead to increased leakage, but also damage the oil film of all sliding parts, which will aggravate the wear of hydraulic components. Therefore, hydraulic oil with slightly higher viscosity should be selected in summer. The normal temperature of hydraulic oil is between 30 ℃ and 55 ℃. When the temperature of hydraulic oil continues to increase, each hydraulic element will expand according to different coefficients, which may also cause stuck fault. It is inevitable to stop and repair at that time. The prevention of high temperature of hydraulic oil depends on daily inspection and maintenance, such as regularly dedusting and cleaning the radiator, which can maintain the heat dissipation performance.

If the temperature of lubricating grease is too high, the lubricating grease will become soft, the adhesion performance will be reduced, and it is easy to lose. At this time, the working device and rotating device will cause high temperature, wear and noise due to poor lubrication. The main causes of grease failure are the shrinkage of gel and the evaporation loss of base oil. High temperature is the main culprit that causes the increase of grease evaporation, oxidative deterioration and serious condensation of oil. Therefore, in summer, it is necessary to select the lubricating grease with good high-temperature performance. It is necessary to maintain the adhesion performance at higher temperature and ensure the slow failure process.

In summer, the vegetation is luxuriant and the insects and birds are active. It is difficult to guarantee that no flying insects will take risks to enter the carriage, no willow fluff will be absorbed into the water tank, and no dead branches and rotten leaves will be plugged into the radiator. These are all hidden dangers that cause high engine temperature, high hydraulic oil temperature deterioration, and poor air conditioning cooling. In addition, for some "old" mini excavators, the hood and sponge at the water tank and radiator are damaged or fallen off, resulting in abnormal fan suction, which may lead to poor heat dissipation.

Excellent operators have good maintenance habits, such as cleaning and removing impurities in their spare time; Pay attention to the number of water temperature tables at all times; When the water temperature is on the high side, idle at a cool place nearby to cool down; Frequently check whether the antifreeze is lacking; It is a good habit to check the tension and fatigue of the fan belt frequently to ensure the healthy construction of the mini excavator. In addition, when the engine temperature of the small excavator is too high, do not stop the engine immediately to prevent the cylinder pulling accident caused by overheating inside the engine, and stop the engine after idling and cooling.

When idle, the equipment should be parked in a cool place to cool down, but do not use cold water to pour tires and brakes to force cooling.

Attention shall be paid to the construction of crawler mini excavator after rain: when the water overflows the rotary gear ring, the lubricating grease in the gear ring shall be replaced in time to prevent the wear of the gear and gear ring caused by mud mixed in the lubricating grease. When wading, do not tilt the excavator more than 15 ° to avoid getting into the water and damaging the radiator. It is rainy in summer, and the track tension cylinder should also be cleaned frequently to prevent rust.

Новости

Новости