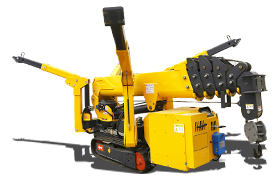

Road roller also need a suitable temperature environment when working. If the road roller is used in an environment exceeding the working temperature, it will bring great damage to the road roller itself.

Due to the hot weather in summer, the engine temperature of the road roller is high, and it is easy to cause failure, resulting in the engine not being able to dissipate heat normally and reducing power. If not regularly maintained the road roller,its engine will lead to the drop of high temperature operation and the lack of oxygen in the lubricating oil, resulting in carbon deposition.

Experiments show that when the engine works in an environment exceeding 30°C, the power of the engine will drop by about 3% for every 20°C rise in temperature. The road roller often works in an environment of 50 °C, indicating that the engine power of the road roller will be lower than normal. High temperature causes the viscosity of lubricating oil to decrease, and it is not easy to form lubricating oil film, which reduces the lubricating effect.

Under the condition of high temperature, the anti-oxidative stability of the lubricating oil of the road roller drops sharply, which directly causes the deterioration of lubricating oil, so that the colloid and sediment of lubricating oil adhere to the surface of piston, cylinder wall and other parts, and the thermal conductivity declines, aggravating the deterioration of lubricating oil. Wear on components. The reduction of the working oil quality of the road roller at high temperature can easily cause extravasation and internal leakage, which reduces the efficiency of the hydraulic drive shaft system and makes the hydraulic drive shaft weak. Therefore, the road roller should try to avoid working in a high temperature environment for a long time.

News

News